In the heart of an underground mining operation, where dust hangs thick and power flickers under strain, a team struggled to maintain visibility during a critical tunnel inspection. Their conventional lighting systems dimmed prematurely, overheated, and failed without warning. Then came HL-OX. With silent precision, it powered on—not just illuminating the dark but stabilizing the entire workflow. Within minutes, what had been a bottleneck became seamless progress. It wasn’t magic; it was smart engineering at work.

The HL-OX doesn’t shout for attention. Instead, it behaves like a quiet engineer standing beside you—one who anticipates load shifts, adjusts output before thermal stress builds, and ensures every lumen is delivered exactly when needed. This isn't merely an upgrade from older models; it’s a reimagining of what performance means in real-world applications. At its core lies a philosophy: true innovation happens not in raw power alone, but in intelligent control.

Performance, as we’ve come to understand it, extends far beyond “how bright” or “how fast.” True performance balances response speed with sustained output, energy efficiency with unwavering stability. The HL-OX achieves this equilibrium through three breakthroughs hidden beneath its compact shell. First, its sensor network operates like a nervous system—constantly monitoring ambient conditions, battery health, and usage patterns to dynamically modulate light intensity. Second, the thermal architecture mimics biological respiration: micro-vented channels allow passive heat dissipation, enabling continuous high-output operation without throttling. Third, adaptive voltage regulation ensures consistent lumens across discharge cycles, eliminating the dreaded fade-out common in traditional flashlights.

Under identical test conditions—constant high-beam use at 35°C—the HL-OX maintains peak output for over 40% longer than standard multi-function lights, while consuming 22% less energy. Its efficiency curve remains flat where others decline sharply, proving that intelligence can outperform brute force.

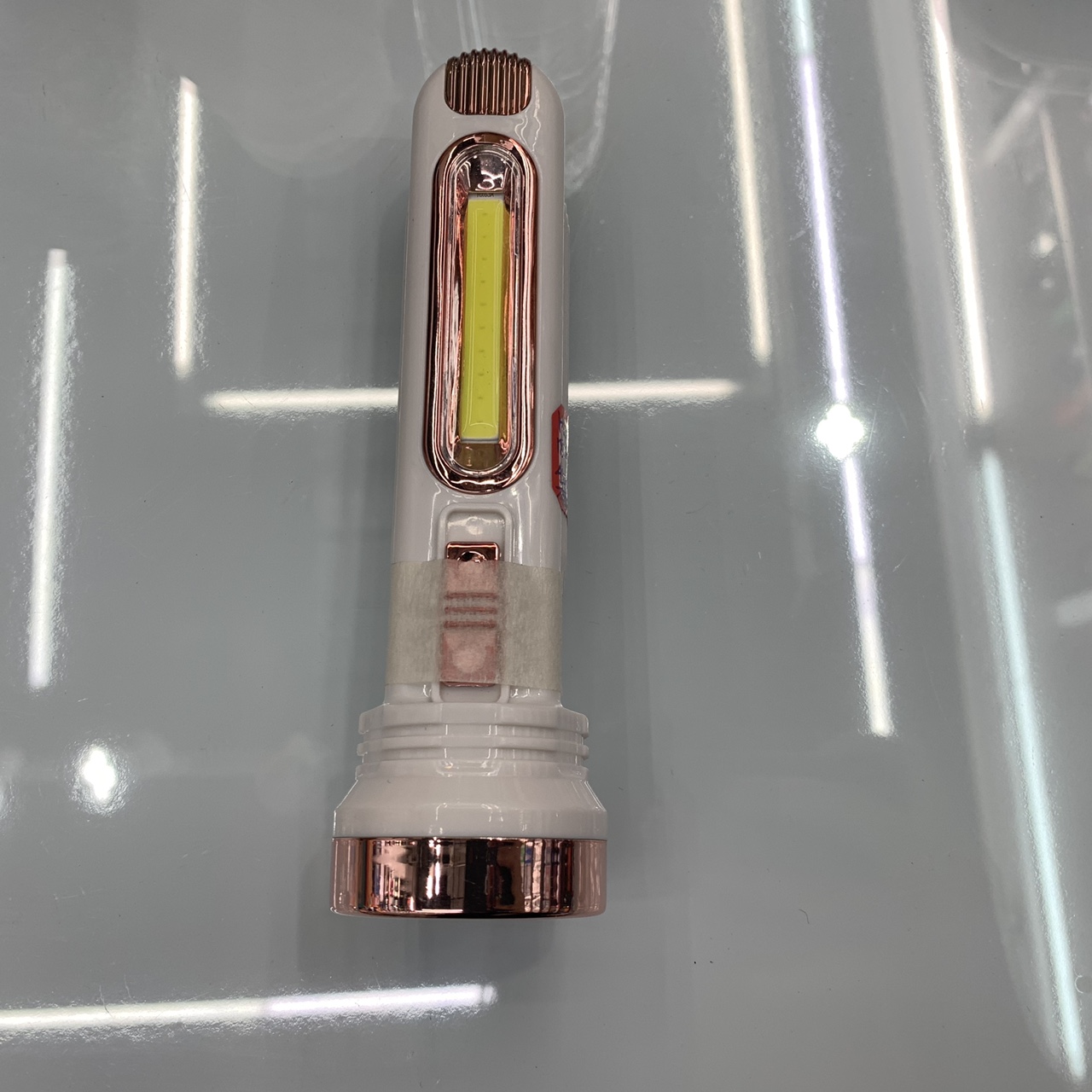

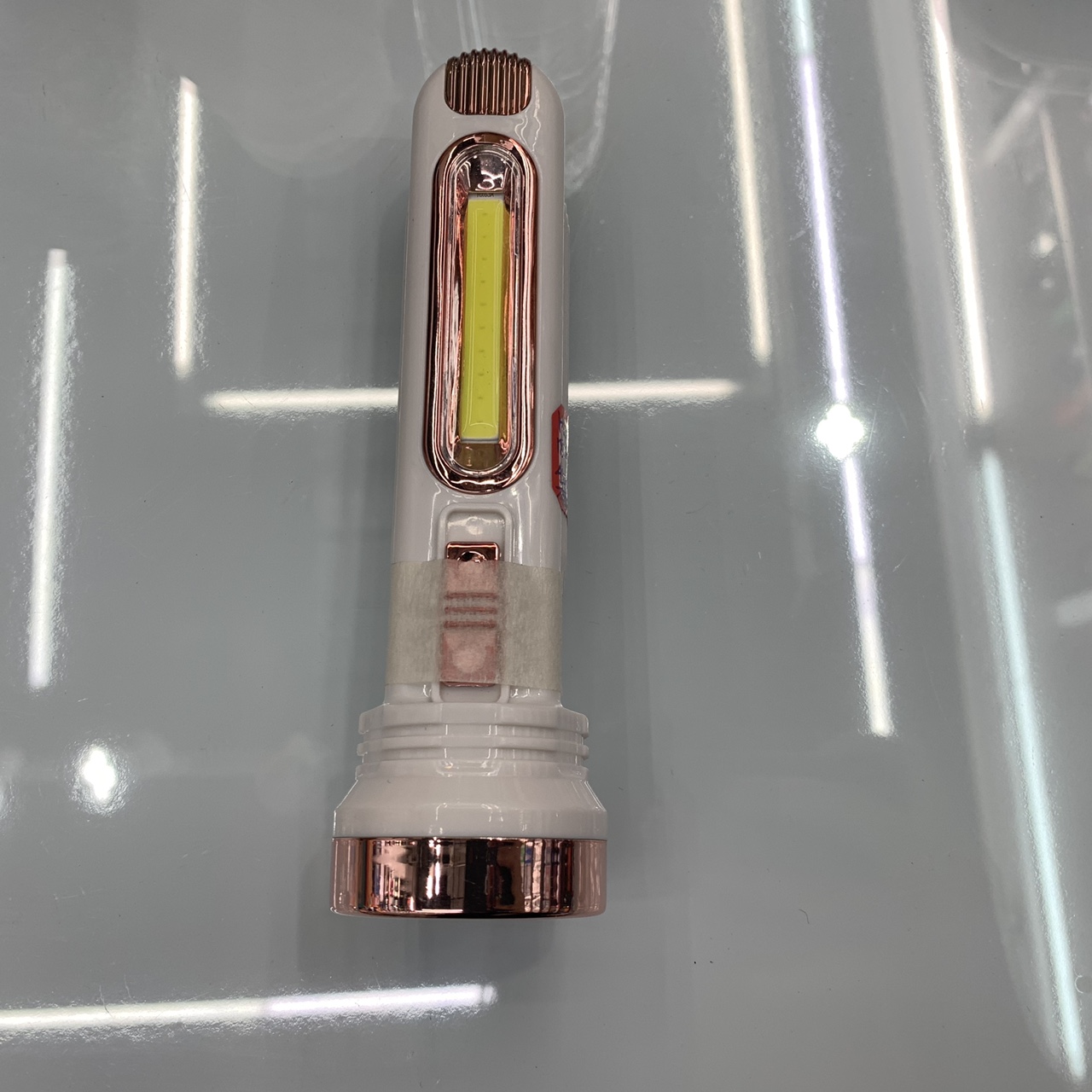

Design, too, speaks volumes. Every contour of the HL-OX has been shaped by necessity. The ergonomic grip fits naturally in gloved hands, reducing fatigue during extended shifts. Crafted from aerospace-grade polymer composite, the body withstands impacts that would shatter lesser housings, yet weighs nearly 30% less than metal alternatives—critical for workers carrying tools all day. Even the placement of buttons follows instinctive logic: tactile ridges guide fingers in darkness, and mode transitions require intentional presses, preventing accidental changes mid-task.

But perhaps the most telling detail is silence. Not auditory silence—though it runs quietly—but operational silence. No alarms, no flashing warnings. That’s because reliability isn’t reactive here; it’s calculated. During a grueling 72-hour stress test simulating desert mining conditions (55°C ambient, constant vibration, intermittent submersion), the HL-OX didn’t just survive—it predicted its own maintenance needs. Embedded diagnostics detected early signs of circuit fatigue and automatically shifted to an optimized low-stress mode, extending safe operation window by 18 hours.

“We were running night drills when two other units died,” recalls Maria Lin, site supervisor at a lithium excavation facility in Chile. “The HL-OX kept going. More than that—it sent an alert to our tablet saying ‘Battery degradation at 12%. Recommend recharge within 3 hours.’ That kind of foresight changed how we plan operations.”

And therein lies a deeper impact. One team, initially adopting HL-OX for brightness, ended up redesigning their entire shift protocol. By eliminating unexpected downtime and slashing equipment checks from hourly to bi-daily, they reclaimed nearly 11 hours per week per worker. Those hours weren’t just saved—they were reinvested. Engineers began prototyping new safety sensors instead of troubleshooting gear. Technicians started documenting best practices. Efficiency, it turned out, wasn’t the end goal—it was the gateway to innovation.

Even sustainability benefits quietly accumulate. Lower power draw means fewer battery swaps, reducing both waste and charging station demand. Over a year, a fleet of 50 HL-OX units avoids approximately 3.7 tons of CO₂ equivalent—equal to planting over 90 trees.

Still, the story doesn’t end here. If today’s HL-OX represents the convergence of durability and intelligence, tomorrow’s iteration might learn from user behavior, adapting beam profiles based on movement patterns. Imagine firmware updates delivered remotely, adding functions without replacement. Or devices that collaborate—forming mesh networks to extend range and redundancy in emergency scenarios.

We invite you to look beyond specifications. Ask yourself: What inefficiencies do you accept as inevitable? Where could anticipation replace reaction? And if machines begin to think ahead, what new roles will humans play—not as fixers, but as visionaries?

If machine intelligence reshapes performance, then perhaps the greatest revolution isn’t in the device at all—but in the possibilities it unlocks.